Propulsion of a Magnetic Material-Applied Microrobot in a Tube Based on a Wireless Power Transfer System

Article information

Abstract

Microrobots can be utilized in various applications, but their ability to move and perform tasks in various environments is especially important. In this paper, we introduce a 3-mm microrobot that can move in a liquid-filled tube, such as a vein, against gravity using an external wireless power transfer-based microrobot propulsion system. The force required to move against gravity was determined by calculating the effects of buoyance and gravity on the microrobot. Based on this information, the current required for the transmitting coil to induce sufficient propulsion was derived using the relation between the incident magnetic field and the magnetic force on a magnetic material. The propulsion system was experimentally tested, and the microrobot successfully moved upward against gravity. In addition, the level of human exposure to the applied electromagnetic field was determined to be within recommended guidelines using the electromagnetic simulation software Sim4Life.

I. Introduction

Improvements in the scaling of technology are having a great impact on the development of medical devices. One promising subject is the microrobot, which is expected to be small enough to move freely along blood vessels [1, 2]. Because of the microrobot’s potential, it is being studied by various research groups [3–7]. To maximize their utility, microrobots are being designed with active circuits. Therefore, to run these circuits, an electric power source is required [8–10]. For this purpose, a wireless power transfer (WPT) system, which transfers electrical energy wirelessly and continuously, is being developed for use with microrobots. If microrobots can be supplied with reliable electrical energy, motor-based propulsion systems can be employed [11, 12]. Although microrobots are capable of generating sufficient propulsion force, the volume of the motor system limits the miniaturization of the microrobot.

To realize a minimized microrobot, microrobot propulsion methods based on the Lorentz force and magnetic force have been introduced [13–18]. These microrobots have demonstrated two-dimensional (2D) movement, such as moving on a water surface. However, to move in a blood vessel, the microrobot needs to perform three-dimensional (3D) movement, since blood vessels are 3D structures.

II. Microrobot with Wireless Power Transfer-based Propulsion

When magnetic material is exposed to an external magnetic field, the magnetic force is applied to the magnetic material, as described in Eq. (1) [16–19]:

where μp, μm, and rp are the relative permeability of the magnetic material, relative permeability of the media, and radius of the magnetic particle, respectively. Several studies have been conducted using this magnetic force as a propulsion force for microrobots [18–20]. Considering that WPT systems are based on a time-varying magnetic field, which is essential for generating induced voltage, the time-varying magnetic field and magnetic material can be used as a source of magnetic force. As a result, the magnetic force on magnetic material, especially a sphere-shaped magnetic particle, when exposed to a time-varying magnetic field, can be obtained as in Eq. (2) [21]:

where ω is the angular frequency of the incident magnetic field of current flows on the transmitting coil. In this research, the medium in which the microrobot will be inserted is a nonmagnetic material fluid. Therefore, the μm is 1. Moreover, the magnetic material has a high relative permeability compared to the fluid, so the μm(μp − μm)/(μm + 2μm) term in Eq. (2) converges to 1. According to Eq. (2), the magnetic force depends on the magnitude, relative permeability, and gradient of the incident magnetic field. To achieve a higher magnetic force, a bar-type magnetic material is applied, which introduces a higher magnetic field gradient. By applying this structure, the receiving coil can be wound along the magnetic material. This concentrates the magnetic field compared to a nonmagnetic material and subsequently achieves higher power transfer efficiency.

As a result, with the magnetic intensity located in a distance (d), Eq. (2) can be modified into Eq. (3):

where v is the volume of magnetic material, I is the magnitude of current flows in the transmitting coil, L is a half-length of rectangular transmitting coil, and d is the distance between the transmitting coil and the receiving coil or microrobot. According to Eq. (3), as the magnetic force on the microrobot is free from the powering frequency, there is no limitation when determining the power frequency. Considering that the magnetic force on a magnetic material at a certain distance (d) is determined by time-varying currents when the required force of the microrobot is given, it is able to determine the current on the transmitting coil.

Accordingly, the design procedures for microrobot propulsion can be organized as shown in Fig. 1. Once the location and purpose of the microrobot are determined, it is possible to derive the required drag force, which allows it to move in a certain range of velocity. In this research, magnetic force can be used as an external force and was determined according to Eq. (3). The microrobot and designed system were then verified experimentally. Finally, an assessment of human exposure to the electromagnetic field level was conducted through a simulation.

III. Propulsion of Microrobot in a Tube

Predicting the required force on a microrobot is essential for designing the system. Many studies apply the drag force (FD) as in the following equation, which is applied to an external flow or free stream condition.

where ρ, v, CD, A are the density of the fluid, the velocity of the microrobot, the drag coefficient, and the cross-sectional area of the fluid, respectively.

Comparing the calculation and simulation results, they correspond to each other, achieving error rates lower than 4%. However, this equation can only be applied to the free stream condition. Since this research assumes that the size of the microrobot is comparable to that of the blood vessel, it is more reasonable to consider the internal flow condition. Because of unpredictable turbulence, calculating the exact equation of the drag force for an internal flow condition is difficult. Instead, the commercial finite element method (FEM) of analysis, Ansys computational fluid dynamics (Ansys CFD) can be used to obtain the propulsion force of a microrobot in tube conditions.

Fig. 2 shows the velocity of the fluid versus the drag force. The drag force on the graph indicates the force required to maintain its position against the stream when the fluid flows past the microrobot at a certain velocity. Considering that the fluid speed in a vein is 3–50 mm/s, the required propulsion force for a microrobot is in the range of 2 μN to 100 μN. On the other hand, in the aorta, whose diameter is 25 mm, the required drag force is around 80 μN to 350 μN. These simulated results suggest that the order of the required propulsion force on the microrobot in the tube is in the a-μN range.

Comparison of drag force in (a) a vein (internal flow condition) and (b) aorta (external flow condition). Dt and Do represent the diameter of the tube and the diameter of the microrobot, respectively.

In this research, we selected the specific velocity of blood vessels in the vein and aorta as 3 mm/s and 200 mm/s, respectively. Under these conditions, the force required to move against the blood flow is described in Fig. 2. As the blood velocity of the aorta is around 70 times higher than that of the vein, the required force on the aorta was evaluated at about 10 times higher than that of the vein. Moreover, as can be expected, the drag force will differ depending on the outer shape of the microrobot. This research considers a capsule shape since the shape of the microrobot is determined by a bar-shaped ferrite.

IV. Experimental Verification

To validate that the μN range of propulsion force or drag force is enough to allow the microrobot to move against gravity, experimental verification was conducted. In general, venous blood is hard to define, according to [2]. For this reason, in this research, we assumed the medium to be an eligible oil and not a vein condition.

1. Experiment Setup

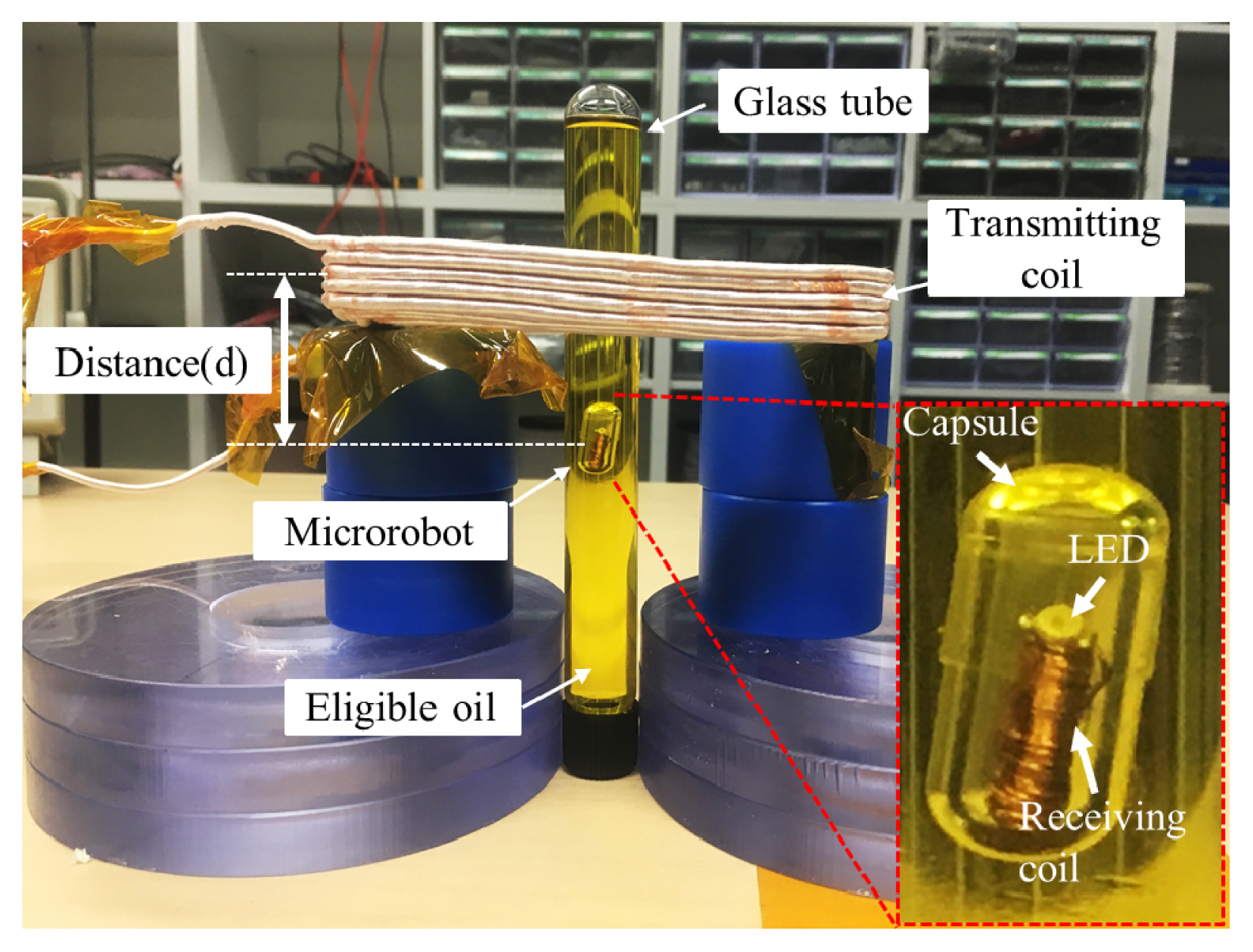

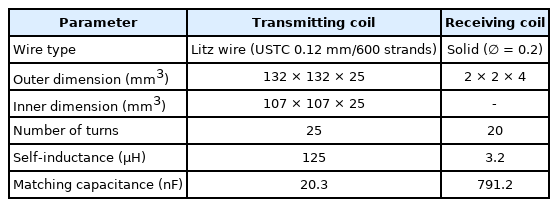

Fig. 3 shows the experimental setup, including a 25-turn transmitting coil and the fabricated microrobot. The receiving coil is wound along a ferrite sheet bar whose relative permeability is 150, and an LED is applied as an active circuit. The microrobot is sealed into a capsule-shaped hydrophilic material. To prevent it from dissolving, the glass tube is filled with oil.

As this research focuses on moving the microrobot upward against gravity, the tube is stood between two blocks. As it is not easy to create a balance between buoyancy and gravity, the experiment started when the microrobot was 5 cm away from the transmitting coil. Detailed electrical parameters and dimensional parameters are listed in Tables 1 and 2.

2. Derivation of Force Required to Move a Microrobot

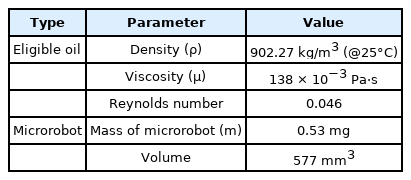

When the microrobot is inserted into the fluid, it is affected by both gravity and buoyancy, as illustrated in Fig. 4. Considering that the mass of the microrobot is 0.53 mg, the gravity on the microrobot can be determined to be 5.194 mN.

Calculated buoyancy and gravity on the microrobot. Since the force of gravity on the microrobot is around 90 μN higher than buoyancy, the microrobot goes down when there is no external force.

Meanwhile, considering that the density of the oil is 902.27 kg/m3 and the volume of the capsule is 577 mm3, the buoyance of the microrobot can be calculated as 5.104 mN, which is 90 μN lower than gravity. Thus, it will require more than 90 μN to move the microrobot upward.

According to Eq. (3), it turns out that a 23-A current on the transmitting coil is required to induce the current needed to generate 90 μN in the microrobot when the distance between the transmitting coil and the receiving coil is 5 cm. When the WPT system is turned off, the time varying magnetic field is not generated, and therefore, there is no external force. In this case, the microrobot slowly moves downward because the gravity is higher than the buoyancy. On the other hand, when the WPT system is activated, the time-varying magnetic field introduces a magnetic force on the microrobot, and this acts like an external force. Since the transmitting coil is located above the microrobot, the external force is applied upward in the transmitting coil direction.

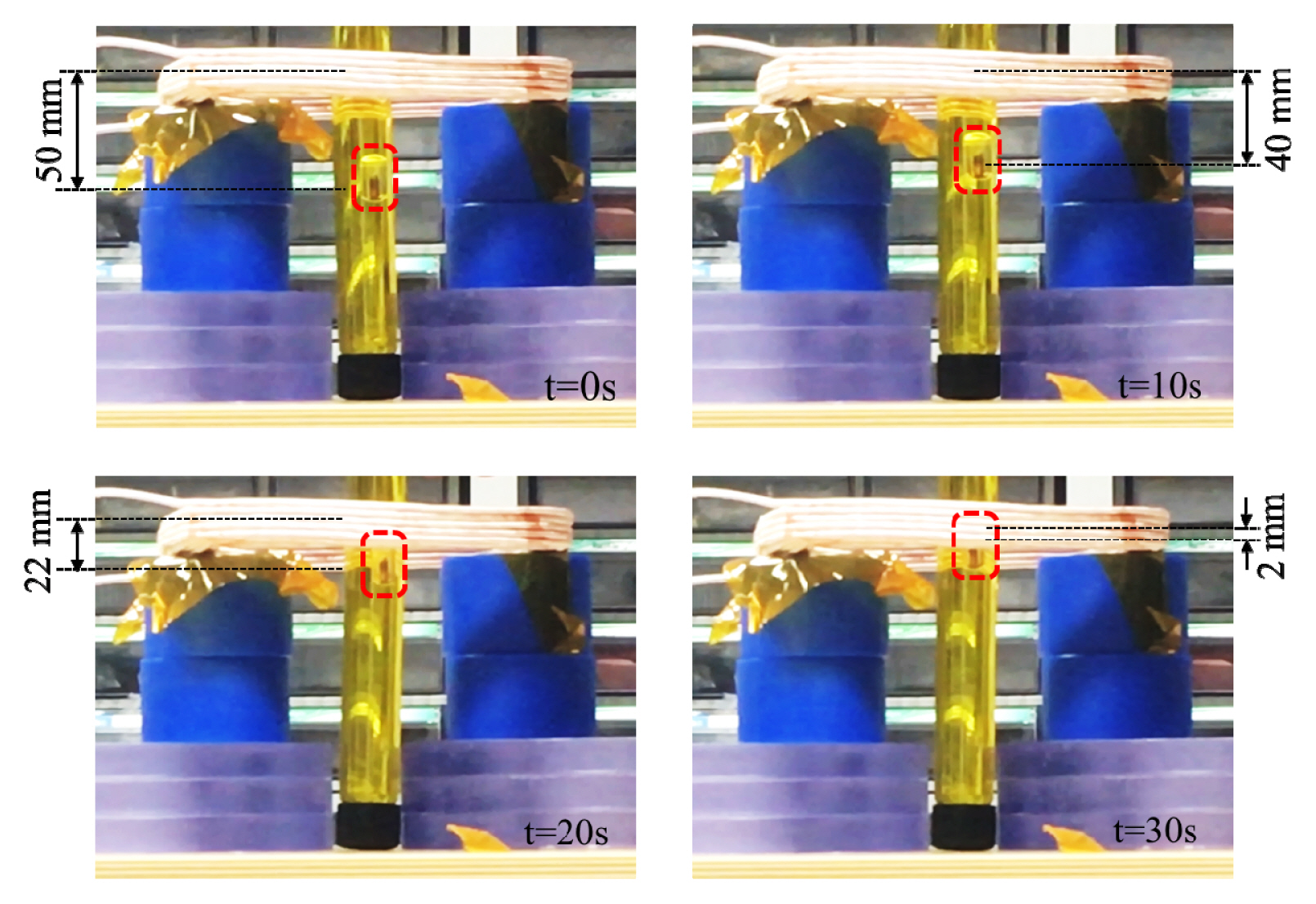

The movements of the microrobot when the WPT system was activated for 30 seconds were captured and are presented in Fig. 5. As time passed, the microrobot moved upward against gravity due to the applied external magnetic force. The time-average speed in 30 seconds was 1.67 mm/s.

Images of the microrobot moving for 30 seconds after the transmitting coil is activated. The magnetic force is enough to move the microrobot against gravity.

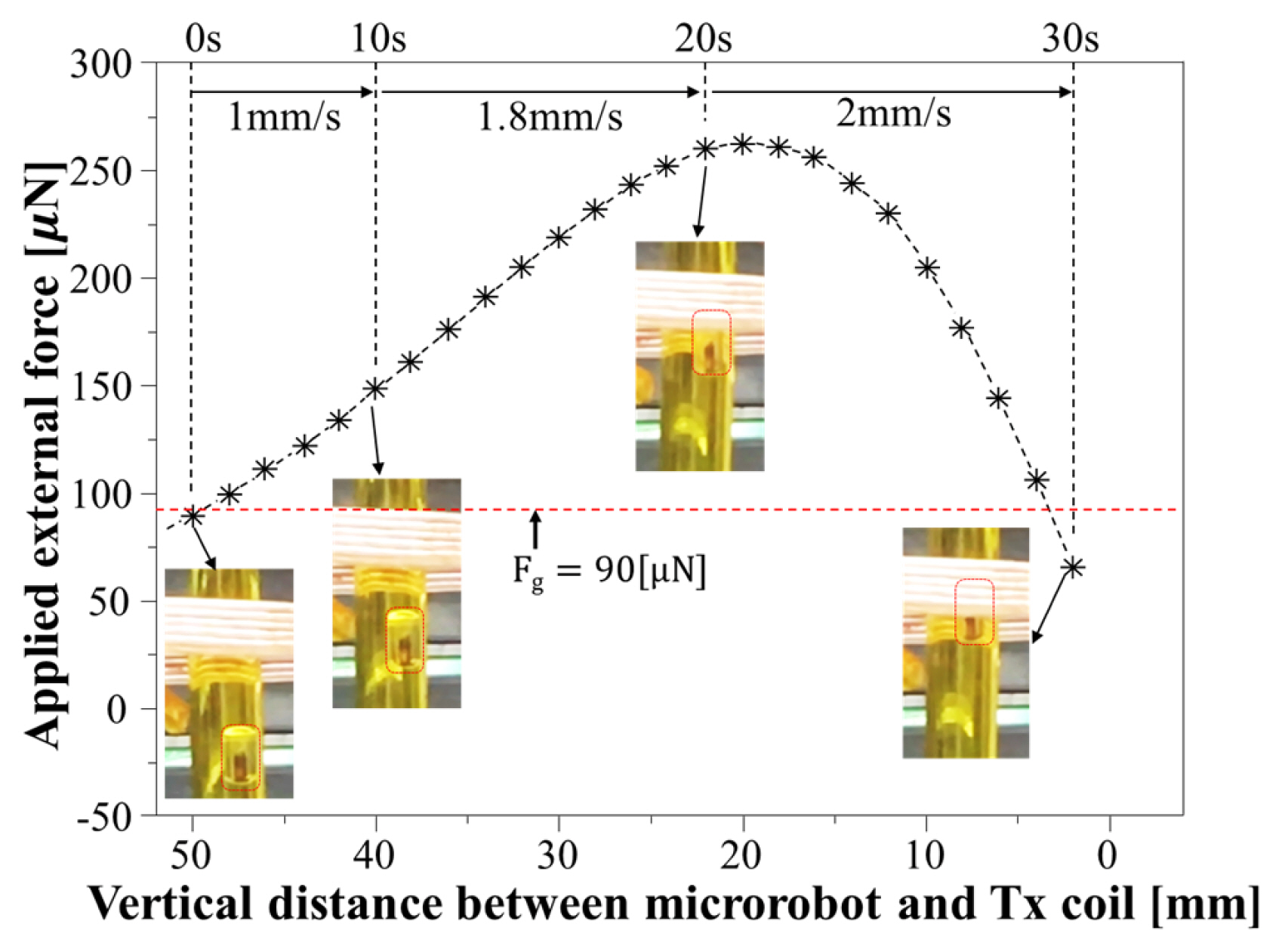

Fig. 6 illustrates the applied external force depending on the position of the microrobot. These values were calculated using Eq. (3), since the current of the transmitting coil, the relative permeability of the ferrite sheet, and the vertical distance between the transmitting coil and the receiving coil are known values. Comparing the force and velocity as the microrobot moved closer to the transmitting coil shows that the propulsion force increased.

Calculated external force depending on the position of the microrobot and measured time-average speed every 10 seconds during movement.

Accordingly, the moving velocity of the microrobot was observed to increase as the microrobot approached the transmitting coil. It turns out the time-average speed of the microrobot at 10-second intervals was 1.0 mm/s, 1.8 mm/s, and 2.0 mm/s. This implies that the microrobot is able to move upward against gravity, achieving a-mm/s range velocity in the fluid.

V. Electromagnetic Field Human Exposure Assessment

Although the proposed system was verified through experiments, before it can be used as an implantable microrobot, it is necessary to evaluate the level of human exposure to the applied electromagnetic field (EMF). For human exposure assessments, the commercial electromagnetic simulation software Sim4Life can be used. Since the microrobot is designed with an operating frequency of 100 kHz, a magneto-quasi-static (MQS) approximation solver is used. The MQS approximation assumes that the induced current in the human body does not interfere with the incident magnetic field, and this is valid for localized exposure from WPT systems below 10 MHz [22]. In addition, according to the International Commission on Non-ionizing Radiation Protection (ICNIRP) guidelines, both the internal electric field and synthetic aperture radar (SAR) should be considered at 100 kHz [23, 24].

To evaluate the internal electric field and SAR, an anatomical human body model, Duke (a 34-year-old male), taken from Information Technologies in Society (IT’IS), was used [25]. The simulation setup for the EMF human exposure assessment is shown in Fig. 7. The transmitting coil was wrapped around the calf, and the receiving coil was placed in a vein. The vertical distance in the z-axis direction between the microrobot and the transmitting coil was 5 cm, which is the same as in the experiments, and the distance in the y-axis direction was 6.4 cm away from the outermost point of the transmitting coil.

Fig. 8 shows the basic restrictions for the general public in terms of internal electric fields, and also shows the simulation result at 100 kHz. The simulated internal electric field was 11.8 V/m, which is less than the basic restriction of 13.5 V/m, so the designed microrobot complies with the guidelines. Fig. 9 shows the local SAR simulation results.

Basic restrictions for the general public in terms of the internal electric field and simulation results.

For the local SAR evaluation, the limits for the head/body or limbs are 2 W/kg and 4 W/kg, respectively, depending on the area exposed to the EMFs. In this simulation, the microrobot was located in the limb, and the simulation result was 0.5988 W/kg, which satisfies the limit of 4 W/kg. Therefore, it was confirmed that the proposed microrobot satisfies the ICNIRP guidelines based on the results of the human EMF exposure assessment through internal electric field strength.

VI. Conclusion

Microrobots have high potential value as implantable devices. To maximize their utility and minimize the size of the microrobot, a wireless power transfer-based microrobot propulsion system is introduced. Considering that the blood vessel is a kind of tube, the microrobot was inserted into a glass tube filled with fluid for experimental validation. Through experimentation, it was shown that a 3-mm microrobot can be moved against gravity, achieving an average velocity of 1.68 mm/s for 30 seconds. Moreover, a simulation was conducted to ensure that the human EMF exposure was within acceptable levels. The results showed that the proposed system satisfies the IC-NIRP guidelines, including the internal electric field strength and SAR evaluation.

Acknowledgments

This research was supported by a Yeungnam University Research Grant (No. 220A580062) and partly supported by a National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2021R1 G1A1004926 and NRF-2017R1A5A1015596). Thanks to ZMT for providing a free license for Sim4Life, which was used in this study.

References

Biography

Dongwook Kim received a B.Sc. degree in mechatronics engineering from Korea Polytech University, Siheung, South Korea, in 2014, and M.Sc. and Ph.D. degrees in green transportation from the Korea Advanced Institute of Science and Technology (KAIST), Daejeon, South Korea, in 2016 and 2019, respectively. In 2019 and 2020, he was a postdoctoral researcher with the Department of Mechanical Engineering Research Institute, KAIST, and the Department of Mechanical and Manufacturing Engineering, University of Calgary, AB, Canada. He is currently an Assistant Professor in the Department of Automotive Engineering, Yeungnam University, Gyeongsan, South Korea. His research interests include wireless power transfer systems in microrobots, implantable devices, and electric vehicles.

Jangyong Ahn received an M.S. degree from the Cho Chun Shik Graduate School for Green Transportation, Korea Advanced Institute of Science and Technology (KAIST), South Korea, in 2018. He is currently pursuing a Ph.D. degree at KAIST. His research interests include EMI/EMC and human exposure to EMF from wireless power transfer systems.

Seungyoung Ahn received B.Sc., M.Sc., and Ph.D. degrees in electrical engineering from the Korea Advanced Institute of Science and Technology (KAIST), Daejeon, South Korea, in 1998, 2000, and 2005, respectively. From 2005 to 2009, he was a Senior Engineer with Samsung Electronics, Suwon, South Korea, where he was in charge of high-speed board design for laptop computer systems. He is currently a Professor with the Cho Chun Shik Graduate School for Green Transportation, KAIST. His research interests include wireless power transfer system design and electromagnetic compatibility design for electric vehicles and high-performance digital systems.